Finally tackled this project to make an record shelf for our currently playing record! We’ve needed one for a while and I couldn’t stomach buying one when I knew it’d be an easy project. Thanks to my wife for being so patient.

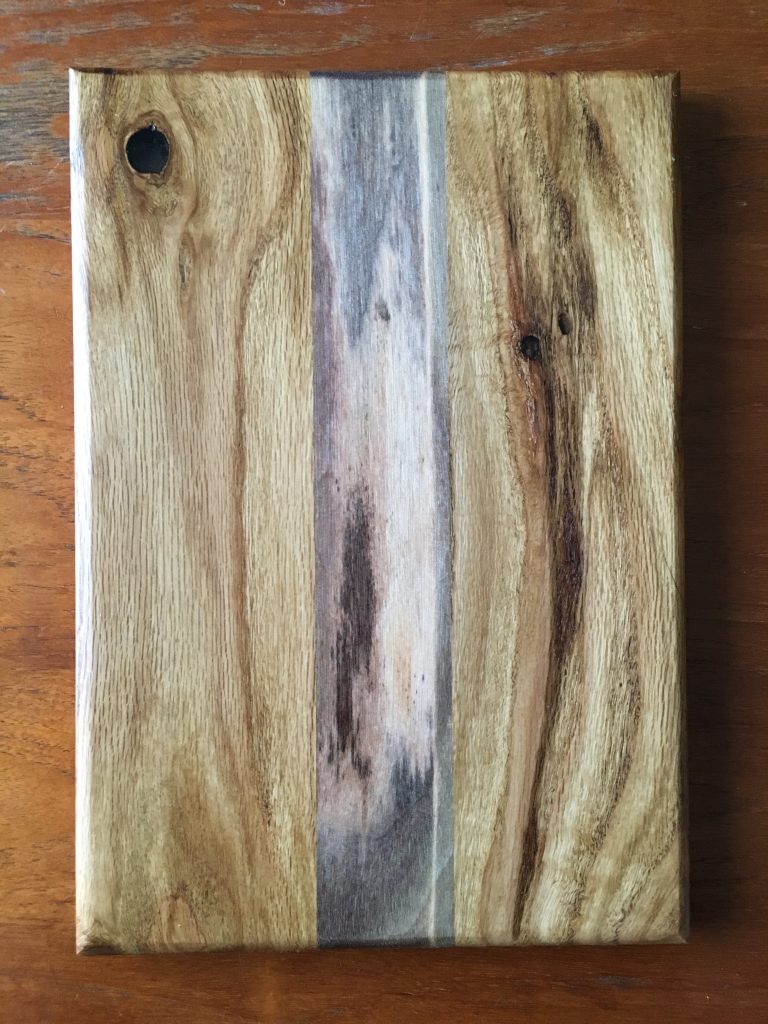

Shelf is made from a single oak board and finished with paste wax and adhered to the wall with brass screws:

Process

I started with a 2″x2″x20″ oak board. I cut it down to length and then raised the table saw blade up and started to remove the middle of it to create the spot where the record sits. Then another pass to shorten the front lip so you can see the full record. After that some sanding to clean it up and soften the edges.

This created a lot of sawdust. The “easier” way to do this would have been to glue up the back, front, and bottom from separate pieces of wood. The aesthetic wouldn’t be the same, but most people wouldn’t notice or care .

When looking around for examples of shelves like this I found that most of these things are hung using keyhole slots. I absolutely hate keyholes though! They assume a lot about the flatness of your wall and are just a pain to get lined up and installed. Made the call to have the screws visible and I’m happy with the result.

(Screws clocked, of course, because I’m not a scrub and don’t want Sam Firke to be disappointed in me.)

Also! I like this detail where the knot is part of the shelf: